|

Burning wood produces environmental impacts. That is why it must be done responsibly. Responsible wood heating should be defended from criticism that it is bad for the environment. In fact it should be promoted on environmental grounds. When we talk about the impact of wood burning on the environment we should consider three distinct forms of impact:

Burn sustainably harvested, properly processed and seasoned fuel in an advanced combustion stove or fireplace that is vented through a chimney that runs straight up through the building. It sounds so simple, but as you can imagine, there are some complex issues and layers of meaning under the surface of the words. Here is a brief explanation.

Properly processed wood is cut to the correct length and split to the correct range of sizes for the appliance. Having wood the right length and range of size makes it easy to build good, clean burning fires. Properly seasoned fuel is split and stacked in an area open to sun and wind for between six and twelve months, depending on how hard the wood is, how large the pieces are and how dry the climate is. You cannot burn without smoke if you are using wet wood. Sustainable harvesting involves selective, uneven age cutting so that an acceptable level of biomass and biodiversity is maintained permanently on the site. Advanced combustion stoves and fireplaces burn wood about 90 per cent cleaner and one-third more efficiently than older conventional appliances. That means a lot less smoke outside and lower forest impacts because less wood is used. And there is a bonus: The same advanced appliance characteristics that result in lower outdoor emissions also result in less chance that smoke will be spilled inside the house. The chimney should run inside the house because if it runs up an outside wall there is a good chance that smoke, odors and cold air will flow backwards into the house, polluting the indoor air. Although there has been a tradition in rural areas of burning garbage in backyard barrels and in wood burning heaters, it is now apparent that when you burn garbage, you're making poison. We should all be working towards environmentally appropriate wood heating. Marlene, a wood burner and one of our visitors, sent us a copy of an article she wrote for her local community newspaper. "Hey Neighbour" is a wonderful contribution to the dialogue on responsible wood heating. Congratulations to Marlene for making a difference in her community. Maybe you could also promote responsible wood heating in your community. You will find several articles here that go into plenty of detail on the environmental impacts of wood heating.

2 Comments

William Bozied, Mother's Residence

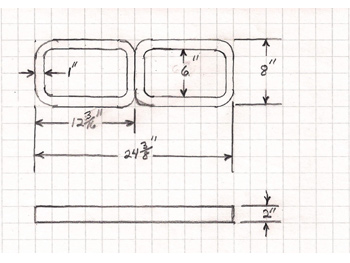

Sterling Heights, Michigan The original in-throat damper (1966) was rusted open and would have cost $1,200 to replace. The open chimney top allowed a mother raccoon with babies to nest there, and a cold draft in the family room. Installation took a half hour for both All Season Control Covers. Problems solved. Project description: Two nine by thirteen flue tiles for one fireplace, two inches of flue tile exposed above the masonry cap. The mounting brackets were modified to accommodate the short flue tile (should be at least three inches), and the center drip edges of the Control Covers were cut off in order to lay flat on the flue tiles. Of course dual controls down to the firebox, one for each Control Cover. Robert Worthley of Kennebunkport, Maine was very pleased with his installation of a custom All Season Control Cover.

Here is what he had to say about the project: Here are photos of the installation and completed project for the chimney top damper which you recently supplied to us. I took the last two photos from the street, which show that the unit is almost invisible from the curb. I'm sure that your product will provide the solution to what has been an annoying problem for that chimney flue. The complete installation took about one hour. I am told that it was an easy process and the quality of your work was superb. I'd be happy to refer any future work of this nature to your company for what is clearly an excellent product. Nice to see that "made in the USA " still means the best! Cape Property & Construction Management was the general contractor for the construction of this house in Kennebunkport Maine. The masonry company which built the chimney and installed your chimney top sealing fireplace damper was Ledgestone Masonry of Kennebunk, Maine. Thanks again for a job well done. It was a pleasure doing business with you. Robert Worthley President-Cape Property & Construction Management, LLC. from woodheat.org

A good chimney and system design produces desirable performance characteristics:

This is good wood stove performance: (hint: it's really the chimney that's doing the performing!)

Think of the chimney as the engine that drives the wood heating system. Think of its fuel as heat. Think of the power it puts out as draft. The more fuel (heat) you give this engine (chimney), the more power (draft) it will deliver. So, the hotter the exhaust gases, the more draft is produced. Draft, by the way, is good. It's the suction that keeps the smoke from coming into the room. Insulation in the chimney is important because it helps to keep the exhaust hot until it is expelled outside, and so, increases draft. The chimney works with the stove or fireplace in a kind of feedback loop. Heat in chimney makes draft, which pulls in more combustion air, which makes the fire burn hotter, which delivers more heat to the chimney which makes more draft and so on. An insulated chimney makes more draft with less heat. In winter, a well-designed and properly installed chimney makes some draft and flows some air upwards, even when no fire is burning. When you build a fire in a stove connected to such a chimney, the kindling ignites easily, draft increases rapidly and you have a nice bright, hot fire right away—and no smoking. This is the kind of system you want in your house. Wondering how to get the most out of your fireplace or wood stove? Woodheat.org has some excellent tips on burning wood correctly to improve efficiency reduce air pollution. In these excellent articles you'll learn about how wood burns so you have a better understanding of how to make wood burning work best for you.

A Concise Guide to High Performance Woodburning How to Build and Maintain a Wood Fire 16" x 16" with custom base Custom All Season Control Cover ready for shipping (duct tape used to keep lid closed during transport) Natural Air Conditioning?

Problem: We have a two story open format log cabin. It has a wood burning stove on the first floor. This question is not about the stove! In the summer, when it is 90 degrees downstairs it is 110 upstairs. On a Scouting campout, one of the Scout leaders said what I needed was a flue in the roof to allow for natural air conditioning. Air would come in thru the downstairs windows and doors and go out the top. Your product, set on top of a raised frame that would make it think it was on a chimney top, looks like it would work perfectly. And we could control it from inside the cabin. Natural air conditioning has a nice ring to it. What do you think? Thanks in advance, Tim Solution: We were able to create an ASSC with a custom base for Tim's cabin roof that let the hot air escape and cool his cabin naturally. Great idea! from woodheat.org

Gulland 1992 Article by Ike Johnson , reprinted from Back Home Magazine.

There are several reasons for choosing wood heat over the few available alternatives. Not the least of these reasons is economy. In New England where I live, for instance, 11.4¢ per kilowatt electric rates can give your mortgage a run for its money if you're unfortunate enough to have electric heat. Wood burning boasts advantages other fuels can't mimic: an evenness, quietness, and aesthetic appeal truly unique to wood. There are many who relish the rituals of self sufficiency involved with getting in their own wood. That's not to say that more is necessarily better. No matter how much you admire the sight of a cut and split stack drying in the autumn air, you owe it to yourself to get by with as short a stack as is prudent for the winter in your locale. Here, then, are five strategies for milking the most Btu's out of every stick you burn. Cut Ahead and Burn Dry Green wood contains up to 50 percent of its weight in water. The first stage of combustion involves bringing this mass of water up to its vaporization point. The energy expended in doing this does not heat your home. And, while steam heat has its place, that place is definitely not in your woodstove. Worse yet, green wood gives off far more creosote than seasoned fuel, which further robs a stove and chimney of efficiency. On top of that, creosote produces the hazard of chimney fires, which have laid many a home to ash. Therefore, by cutting firewood a full year or more in advance, you theoretically could halve the amount of wood required to heat your home. Buying or cutting two years' worth of fuel may take some up front money and discipline, but it' s an investment that pays for itself quickly in dollars, effort, and safety Keep It Dry As obvious as it may seem, let me emphasize that wood cannot dry out beneath a mantle of snow, under a tight fitting tarp, nor pressed three inches into the mud and grass. Many businesses discard used pallets; these can serve as excellent platforms to get each and every precious stick up off the ground where it can dry. Keep stacks of wood separated so that air can flow easily through them. Avoid the temptation to pile row after row end to end, because the wood in the center will not have enough circulation to dry properly. If you have much choice as to where to place a stack, orient it with sun light and prevailing winds working to your advantage. Likewise, avoid if possible over hanging eaves, trees, and structures that can funnel rain onto your fuel. If the stack is against a wall, provide shelter from the dripping roof. Better still, build a woodshed. It would probably take less effort than chasing your windblown tarps after every gale. Here' s a money saving tip for those who do rely on tarps to protect their woodpile from the elements: use old ragged tarps to cover the newer ones and thus shield them from destructive ultraviolet light. Of course, the best strategy for those who enjoy plenty of room is to get all wood indoors before the rain and snow starts to fly. An attached garage or a basement not only spares the seasoned wood from the elements but spares you those midnight trips outdoors in your nightclothes and galoshes, all the time allowing your firewood to continue drying throughout the winter. Burn Efficiently Another great energy saving potential lies in upgrading your stove. While the initial outlay is high, you can be certain that the payback from increased efficiency will be seen within a reasonable time. As of 1994 the EPA has required that all woodstoves sold in this country meet emission control standards. The way most stove manufacturers have complied is through the use of catalytic converters, similar to those in a car. But unlike those in automobiles, catalytic converters in stoves make them run more efficiently, as well as discharge fewer pollutants into the atmosphere. A new woodstove with a catalytic converter is rated at nearly 76 percent efficiency. Other stove makers rely on "high tech"designs that are specially insulated and engineered to use airflow and secondary combustion to bring efficiency up and particulate emissions down. These burners typically are compact and not quite the performers that catalytic stoves are, but they're not as expensive, either. Compare the efficiency of the new models with your current stove and decide whether it's worth the expense of upgrading. If you're now using a home built variation of the barrel stove, for example, as much as 75 percent of your fuel could be going up and out of your chimney as dirt and heat. Another robber of fireplace efficiency is a clogging accumulation of ash. On the next warm day, let the fire burn out so you can remove those built up ashes. Also keep in mind that a small vigorous fire is more efficient than a large smoldering one, both in terms of heat output and creosote production. Keep the Heat In Naturally, a well insulated home requires less fuel than a poorly insulated one. There is much you can do to control this form of heat loss even after the home is built. You could hire an energy auditor with gadgets galore to come tell you where you are losing heat, or you can try the barefoot test: the next time a cold wind is blowing, take a stroll barefoot around the perimeter of your interior. Your tootsies can provide a valuable input on where heat is escaping.The remedies are beyond the scope of this particular article, but a local hardware store can counsel you on what can be done at what price. It may be as simple as stuffing loose insulation in your attic or as involved as replacing your windows with insulated casements. In any event, try to convert the anticipated cost into cords of wood over the lifespan of the improvement. If you're trying to talk yourself into a given project, factor in convenience and comfort. If not, leave it on a dollars and cents basis. Burn the Best Another way to get the most out of your wood is to be a snob; all trees are not created equal. Go for as good a grade of fuel as possible. Assuming 90 cubic feet of solid wood per cord (and remembering that an actual 128 cubic foot cord has lots of air space in it), dry hickory has 24.8 million Btu of energy compared to a tepid 13 .5 million for dry fir. A neighbor once observed that burning poplar in the "old days" usually resulted in pregnancy, referring, of course, to another popular method of keeping warm on a winter's night. Nonetheless, his point about poplar being a poor choice heatwise was valid: given the limited amount of time I had to spend on gathering and processing wood, and the limited amount of storage space, the "free" poplar I was splitting was no bargain. Ask various wood suppliers what kinds of wood they offer (see the heat comparison chart) and in what proportion. Insist on a standard unit of measurement. Face cords, ricks, racks, and tons are all in use, but for comparison use true 4' x 4' x 8' ( 128 cubic foot) cords. Determine what is meant by "seasoned." The dealer may mean a single season (i.e., one winter; not much drying time there) or a full year, which is a decent period for split wood to cure to its full potential. Also, consider the characteristics of the wood in regard to cutting and splitting. The same neighbor with his poplar observation claimed that a cord of elm would last half a lifetime. By then, he maintained, you'd have given up on ever getting it split. These recommendations are not speculative. In the nine winters we have spent in our home, we have pared down our wood usage from a whopping 6.5 cords to precisely 4. The mess stays down in the basement, and the house is much more comfortable than it was in the old days. The benefits are tangible and real . . . in dollars, comfort, trips to the chiropractor, and wear and tear on the saw. And best of all, our savings no longer leave the house via the chimney. "Fireplaces are inherently cleaner than stoves". - Paul Tiegs Almost every fireplace tested in accordance with the Washington State fireplace standard, designed to be "equivalent" to the EPA Phase II stove standard, passed. Some fireplaces, like Rumfords and Rosins, tested two or three times cleaner than the stove standard. (See Rumford Test Results.) So, why do so many people think fireplaces are dirty and inefficient? It all began nearly thirty years ago when the American Lung Association tried to get the EPA to regulate the air-tight European stoves that flooded the US market during the energy crisis of the late 1970's and early 1980's. Americans didn't know how to use the stoves and allowed them to smolder as they bragged to their friends how long they could bank a fire. The Lung Association eventually had to sue the EPA which did not want to get into regulating on a retail basis. It was easier to regulate industry than to dictate what people could do in their own homes. The suit brought against EPA resulted in a very narrowly drawn "smoldering stove" standard. Fireplaces, masonry heaters and other "inherently" clean-burning appliances were exempted. See details) The American stove industry and their association, the Hearth, Patio & Barbecue Association, grew up developing stoves that would pass the EPA emissions standards - and, while they were at it, keep the European stoves out of the US market and buy up or put out of business all the small US stove manufacturers. After thirty years of testing and marketing American stoves, is it any wonder that most of the scientists who do the testing and most of the people who write the articles and research papers work for or are paid by the stove manufactures? Not that they were not objective, especially the scientists running certified independent test labs, but they all had an interest in showing how clean the new and improved American stoves were compared with the bad old stoves and fireplaces. ( For example see Skip Hayden's anti fireplace article.) People who liked and understood fireplaces were not the ones testing fireplaces. Rather it was people who had an interest in showing how bad fireplaces were and how good stoves were who tested fireplaces. How could that be? Does General Motors hire Ford to do marketing? Why didn't the masonry industry take an interest? Suffice it to say fireplaces were "exempt" and the masonry industry, organized like a farmers cooperative, wasn't focused. Who should take responsibility for masonry fireplaces? Masons? Brick and block manufacturers? Flue liner or firebrick manufacturers? Independent dealers who sell the materials? Well none of us took responsibility. We were all out to lunch. We just watched masonry fireplaces denigrated and our markets slip away. Some fireplaces, like Rumfords and Rosins, have tested as clean or cleaner than EPA certified stoves. With more testing, fair standards and more time, we will find even more improvement. What we need are clear objective performance standards and rules that allow fireplaces that meet the same performance standards that the stoves that are allowed meet. We are now working on an ASTM national consensus fireplace emissions standard that EPA will recognize. For much more information about fireplace testing and the politics of fireplace certification, see Rumford's article on Emissions.

Here is the letter we received from Mr. Jacobs: DW, Outside Dimensions - (long side) 36 1/2" Inside Dimensions - (long side) 29 3/8" Outside Dimensions - (short side) 32" Inside Dimensions - (short side) 25 3/8" I have included a few more pictures. One is a shot looking down the chimney. You can see the split which I hear is called a "Y" design. There are 3 fireplaces, 2 on one side and one on the other. However, there is a belief that there is a 4th one that was covered up years ago which would explain why there is a "Y" design. These 300 year old houses have a lot of mystery. Regards, Jeff Jacobs Using his photos and drawings, we were able to create a split lid cover with a ring built in to support the stove pipe. Here is what the finished product looks like: This 300 year old house will be now able to keep those chilly winter drafts from blowing through the fireplaces.

Does your home have a unique chimney? Let us design the perfect solution for you. |

See Our WorkAn All Season Control Cover in action speaks for itself. See how our product solves many types of chimney and fireplace issues. Archives

September 2015

Categories

All

|

RSS Feed

RSS Feed